Innovative Technology of Fire Prevention

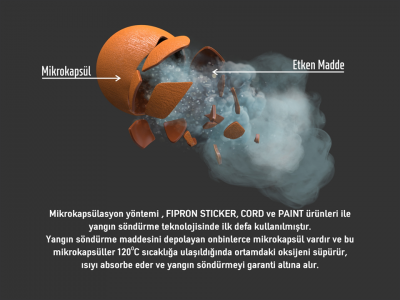

Today, various composite materials capable of fire prevention are created with FIPRON technology. The structure of such materials includes microcapsules, which are fire-resistant active substances. When the activation temperature is reached, the capsule shell bursts and discharges the gas inside. When this gas comes into contact with open fire and burning surface, it sticks and replaces oxygen. It cools the combustion site quickly and thus prevents flare-up quickly and effectively. Products of various shapes and sizes produced with FIPRON Technology can remain in “standby mode” for years and automatically extinguish the flame as soon as it occurs without allowing it to grow.

Sticker

It is a self-running, automatic regional fire-prevention product designed with the application of FIPRON Technology. It has been invented as a protection against the flammability of electrical sockets, distribution boxes, power distribution panels. It is a flexible, composite fire protection plate carried by the adhesive substrate. Carrying the risk of fire caused by electricity; It maintains an area of 0.2-60 liters. It is adhered to the inner ceiling of the volume to be protected as a bed.

When it reaches the activation temperature, FIPRON STICKER releases the active extinguishing agent and prevents the fire at the initial stage. Since this substance is ozone-friendly, it can be used in industrial facilities, residences and various areas.

Cord

CORD is a composite material that is a mixture of heating compound and microcapsule. By calculating the volume of the area to be protected, the required amount of CORD is used by placing it on the points seen as potential sources of exacerbation. Although it protects the area from 50 liters to 300 liters in closed volumes of 1 meter, it may vary depending on the interior design of the protected area. Activation begins at any point on the CORD with the effect of the exacerbation and the active substance is released in the gas phase and prevents fire.

The CORD product is covered with a high temperature resistant gas permeability mesh to maintain mechanical strength and solid products of the reaction. This mesh also has an important functional feature, affecting the active substance discharge rate along the length of the product.